Soft_slide_Fe#

dl 可以改 论文里是 1 5 10 30 60 目前是 1

clc;clear;close all;

cd("D:\桌面\毕设\材料\摩阻扭矩\MATLAB")

trajectory_parameters = xlsread('LH11-1-B4H3.xlsx','轨道','A2:C10000'); % 读取轨道数据,依次为井深、井斜角、井斜方位角

pipe_parameters = xlsread('LH11-1-B4H3.xlsx','管柱数据','C5:G16'); % 读取套管柱数据,依次为内径,外径,接头外径,强度,长度

well_parameters = xlsread('LH11-1-B4H3.xlsx','井身结构','A2:C3'); % 读取井身结构数据,依次为1上层导管下入深度,2上层套管内径,3井眼直径

drill_parameters = xlsread('LH11-1-B4H3.xlsx','钻进数据','A2:G10000'); % 读取钻进数据,依次为1井深,2钻压,3钻头扭矩,4转速,5管柱运动速度,6排量,7钻井液密度

HK_TOR = xlsread('LH11-1-B4H3.xlsx','测量值','A2:C1000'); % 读取1井深2钩载3转盘扭矩

%% 滑动钻进

[alpha,k,kal,kph,tau,dk_ds,tz,nz,bz,dalpha_ds,dpha_ds]=traj_para_linear(trajectory_parameters); % 自定义函数计算插值后的计算轨迹参数

[m,n] = size(drill_parameters ); % 钻进数据长度

depth_start = ceil(drill_parameters(1,1)); % 钻进开始井深

depth_end = floor(drill_parameters(m,1)); % 钻进开始井深

mu1 = 0.1566;

mu2 = 0.2697;

mu_cal = [mu1,mu2];

dL = 1;

for i = 1:m

depth_i = drill_parameters(i,1); % 钻进井深

if depth_i <= 3717

pipe_parameters_i = pipe_parameters(1:5,:);

well_parameters_i = well_parameters(1,:);

else

pipe_parameters_i = pipe_parameters(6:10,:);

well_parameters_i = well_parameters(2,:);

end

drill_parameters_i = drill_parameters(i,:);

[Fe,wc] = drill_slide_soft_cal_Fe(depth_i,pipe_parameters_i,well_parameters_i,drill_parameters_i,alpha,k,tau,dk_ds,tz,nz,bz,mu_cal,dL,0);

Hookload(i,:) = Fe(1)/1000; % 记录相应深度处的大钩载荷值

depth_cal(i,:) = depth_i;

WC(i,:)=wc(1)/1000;

end

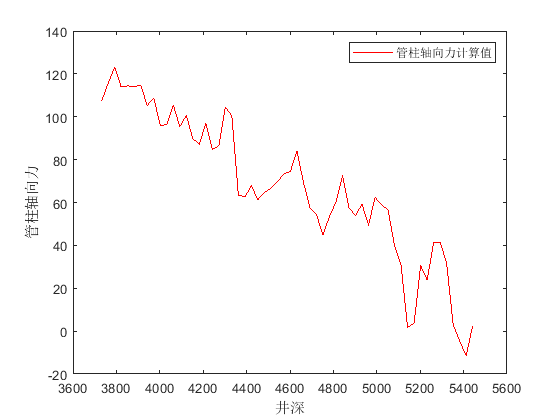

figure('Name','大钩载荷');

plot(depth_cal,Hookload,'r');

hold on;

xlabel('井深'); % x轴标签

ylabel('管柱轴向力');

legend("管柱轴向力计算值")

hold off;

figure('Name','屈曲接触力');

plot(depth_cal,WC,'b')

hold on;

xlabel('井深'); % x轴标签

ylabel('屈曲接触力');

legend("屈曲接触力")

hold off;

管柱轴向力#

function [Fe,wc] = drill_slide_soft_cal_Fe(depth_i,pipe_parameters_i,well_parameters_i,drill_parameters_i,alpha,k,tau,dk_ds,tz,nz,bz,mu_cal,dL,op) % 大钩载荷计算函数

depth_i = floor(depth_i); % 轴向力和扭矩计算井深

if depth_i == 0

Fe = 0;

wc = 0;

return;

end

rpm = drill_parameters_i(4); % 对应测深处的转速

vp = drill_parameters_i(5); % 对应测深处的钻速

den_m = drill_parameters_i(7); % 对应测深处的钻井液密度

if op == 0 % 旋转钻进

wob = -drill_parameters_i(2); % 对应测深处的钻压

tob = drill_parameters_i(3); % 对应测深处的钻头扭矩

mu_op = 1;

elseif op == 1 % 旋转下入

wob = -0; % 对应测深处的钻压

tob = 0; % 对应测深处的钻头扭矩

mu_op = 1;

elseif op == 2 % 旋转上提

wob = -0; % 对应测深处的钻压

tob = 0; % 对应测深处的钻头扭矩

mu_op = -1;

end

if mod(depth_i,dL) > 0

depth_cal = [[0:dL:depth_i]';depth_i]; % 计算井深

else

depth_cal = [0:dL:depth_i]'; % 计算井深

end

length_cal = length(depth_cal); % 计算井深的数据长度

%%

E = 2.06*1.0e11; % 钻杆弹性模量

g = 9.8; % 重力加速度

den_s = 7850; %钻柱的密度 kg/m3

di_array = pipe_parameters_i(:,1); % 钻柱内径

do_array = pipe_parameters_i(:,2); % 钻柱外径

dc_array = pipe_parameters_i(:,3); % 钻柱接头外径

L = pipe_parameters_i(:,4); % 钻柱长度

m_array = pipe_parameters_i(:,5); % 线密度

%% 轴向力和扭矩

Fe(length_cal,:) = wob; % 底部轴向力为wob

for j = length_cal:(-1):2

depth_j = depth_cal(j) + 1; % 正计算井深+1

if depth_j < well_parameters_i(1) % well_parameters(1)为上一层套管深度,摩阻系数分段,套管和裸眼

mu = mu_cal(1); % 套管摩阻系数

dw = well_parameters_i(2); % 上层套管内径

else

mu = mu_cal(2); % 裸眼摩阻系数

dw = well_parameters_i(2); % 裸眼井段直径

end

if depth_j > depth_i-L(5)

do = do_array(5); di = di_array(5); dc = dc_array(5); wp = m_array(5)*g;

elseif depth_j > depth_i-L(5)-L(4)

do = do_array(4); di = di_array(4); dc = dc_array(4); wp = m_array(4)*g;

elseif depth_j > depth_i-L(5)-L(4)-L(3)

do = do_array(3); di = di_array(3); dc = dc_array(3); wp = m_array(3)*g;

elseif depth_j > depth_i-L(5)-L(4)-L(3)-L(2)

do = do_array(2); di = di_array(2); dc = dc_array(2); wp = m_array(2)*g;

else

do = do_array(1); di = di_array(1); dc = dc_array(1); wp = m_array(1)*g;

end

wbp = (1-den_m/den_s)*wp; % 单位长度钻柱浮重,假定管柱内外流体密度相同

%%

I = pi/64*(do^4-di^4); % 截面惯性矩

mu_d = mu; %轴向摩阻系数

mu_t = 0; %周向摩阻系数

if j == length_cal && mod(depth_i,dL)~=0

dL_Mt_Fe = mod(depth_i,dL);

else

dL_Mt_Fe = dL;

end

%%

wc(j,:) = ((-Fe(j)*k(depth_j)+wbp*nz(depth_j))^2+(wbp*bz(depth_j))^2)^0.5/(1+tau(depth_j)^2*mu_d^2*(do/2)^2)^0.5; %接触力计算

if wc(j,:) == 0

wc(j,:) = 1e-6;

end

sin_theta(j,:)=(wbp*bz(depth_j)-(-mu_d*tau(depth_j)*do/2)*(-Fe(j)*k(depth_j)+wbp*nz(depth_j)))/(wc(j)*(1+(mu_d*tau(depth_j)*do/2)^2)); % 接触角正弦值

cos_theta(j,:)=(-Fe(j)*k(depth_j)+wbp*nz(depth_j)-tau(depth_j)*mu_d*wc(j)*do/2*sin_theta(j))/wc(j); %接触力余弦值

%% 管柱屈曲判断

l = 11.3; % 套管单根长度

ltj = 0.2; % 接头长度

de = do*(l-ltj)/l+dc*ltj/l; % 管柱有效外直径

re = (dw-de)/2; % 有效外环隙

if Fe(j) < 0 && abs(Fe(j)) >= 2*(E*I*wc(j)/re)^0.5 && j >2 % 正弦屈曲临界载荷判断

if (abs(Fe(j)) >= 2*(2*2^0.5-1)*(E*I*wc(j)/re)^0.5 && alpha(j) > 1*pi/180) || (abs(Fe(j)) >= 5.55*(E*I*wbp^2)^0.5 && alpha(j) <= 1*pi/180) % 螺旋屈曲临界载荷判断

wc(j,:) = re*Fe(j)^2/(4*E*I); % 螺旋屈曲接触力

else

wc(j,:) = re*Fe(j)^2/(8*E*I); % 正弦屈曲接触力

end

end

%% 迭代求解

Fe(j-1) = Fe(j) - dL_Mt_Fe*(mu_d*wc(j)*(1-k(depth_j)*dc/2*cos_theta(j))-wbp*tz(depth_j)); % 迭代求解管柱轴向力

end

end